A new path to high-efficiency micro-LEDs

A selective thermal oxidation that eliminates damage to sidewalls is set to enhance micro-LED efficiency.

About

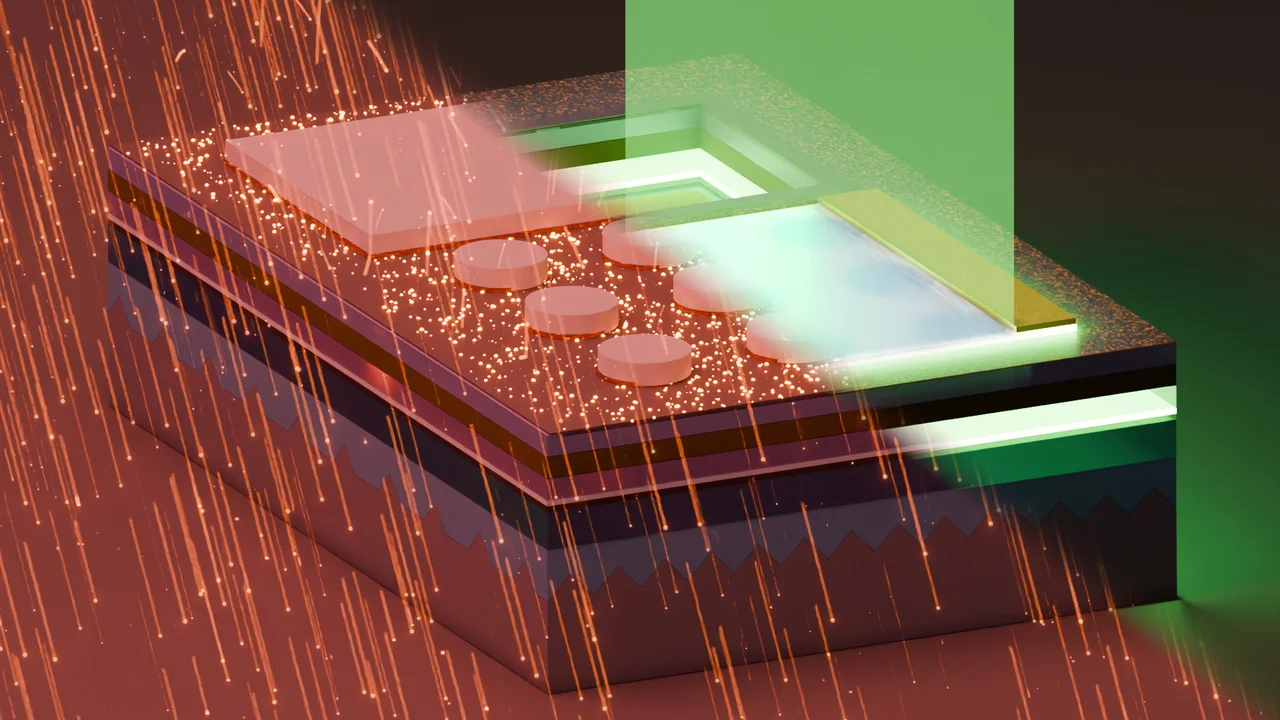

A more efficient way to produce micro-light-emitting diodes (micro-LEDs) — the frontrunners to lead next-generation display technology — avoids a damaging plasma etching step. Now, a selective thermal oxidation approach that uses a unique etching-free process, developed at KAUST, is expected to boost device efficiency.

Micro-LEDs are favored for next-gen displays because of their exceptional contrast ratio, brightness, sunlight visibility and longevity. They are multilayered semiconductor optoelectronic devices that consist of a hole injection layer, an indium gallium nitride (InGaN)-based active layer for light emission and an electron injection layer.