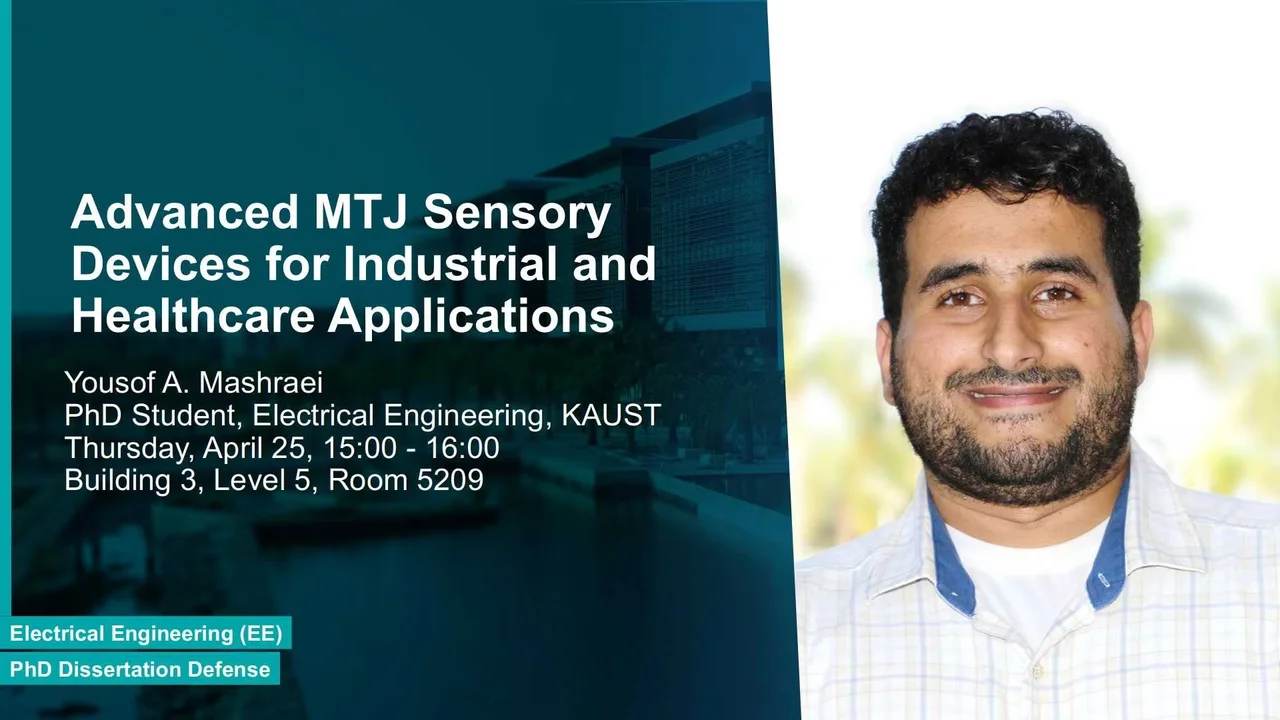

Advanced MTJ Sensory Devices for Industrial and Healthcare Applications

Magnetic sensors are deployed in many applications such as automotive, consumer electronics, navigation and data storage devices. Their market’s growth is driven by demands of higher performance and more integration; primarily to assist in the advancement of Internet of Things (IoT) and smart systems.

Overview

Abstract

Magnetic sensors are deployed in many applications such as automotive, consumer electronics, navigation and data storage devices. Their market’s growth is driven by demands of higher performance and more integration; primarily to assist in the advancement of Internet of Things (IoT) and smart systems. Challenging obstacles of miniaturization and power consumptions must be overcome. A leading sensor that has the potential to accelerate the advancement is the magnetic tunnel junction (MTJ) devices.

Corrosion causes catastrophic consequences especially for industries. Preventive measures could save up to 35% of annual corrosion-related costs. An advanced corrosion sensing technique is developed based on magnetic iron nanowires. The magnetization of these nanowires decays upon their corrosion. This magnetization loss is monitored using a sensitive MTJ sensor. Combined, the nanowires and the MTJ sensor realize a highly integrated sensor concept that enables corrosion sensing with an ultra-low power consumption of less than 1 nW, a sensitivity of 0.1 %/min, a response time of 30 minutes and an area of 128 μm2.

Surgical tool development is accelerating in the healthcare sector. Cardiac catheterization specifically is a minimally invasive surgery that relies heavily on x-ray imaging and contrast dyes, which are harmful to the patients. A flexible tri-axis MTJ sensor is developed to help minimizing the need for x-ray imaging during the procedure.

The flexibility of the sensor is demonstrated by bending the sensor to a diameter of 500 μm without compromising its performance. The sensor also demonstrated a high reliability even after 1000 bending cycles without fatigue. Three flexible sensors are mounted onto the tip of a 3 mm cardiac catheter, realizing a novel tri-axis sensor-on-tube concept. The sensor has a high sensitivity of 9 Ω/° and an MR ratio of 29%. It weighs 16 μg only and adds 5 μm to the catheter’s diameter.

Brief Biography

Yousof Mashraei received the M.S. degree from King Abdullah University of Science and Technology (KAUST) in 2014. He joined King Abdulaziz City for Science and Technology and was involved in smart grid and renewable energy since 2012. He joined KAUST as a PhD student in 2014 and specialized in microfabrication and sensors. His research focus on magnetic sensors, integration and hybrid system for health and industrial applications.