They Got Dye With A Little Help From Their Friends

An industrial wastewater research problem shared is a problem halved, shows a multiteam project.

About

When Jung-Hong Min developed a flexible membrane-like material made of gallium nitride, some of his samples turned out to be electrically “leaky” for the LED or laser applications he had in mind. But when Min presented the results to his colleagues in Boon Ooi’s research group, they captured the attention of graduate student, Huafan Zhang. “I thought, well they might not work very well for your applications, but they could be perfect for me,” Zhang says.

Rather than use the nanostructured, semiconducting gallium nitride membrane as a light emitter, Zhang hoped to use it to harvest light energy instead. She wanted to try out the material as a sunlight-driven photocatalyst for breaking down organic contaminants in wastewater.

“I thought, well they might not work very well for your applications, but they could be perfect for me.”

“Min gave me a small sample of the material, just one centimeter by one centimeter — but initially, he didn’t expect it to work,” Zhang recalls. Undeterred, Zhang tested the membrane’s capability to break down an organic dye, which can be a major component of industrial wastewater from textile and cosmetics production, as well as household laundry wastewater. She found the membrane could break down a dye called methylene blue.

“I told Min, we have to work together on this,” Zhang says. The team went on to show that, when illuminated with light, the membrane would react with water to generate reactive oxygen species, mainly hydroxyl radicals, which would attack and decompose the dye.

Buoyed by the success, Min attempted to make a larger sample of the membrane, the size of a 2-inch wafer. “Scaling up these flexible semiconductors is very difficult, but with a lot of optimization, he managed it,” Zhang says. “But now the problem was thrown back to me, because the membrane was too large for the solar simulator we have in the lab,” she says.

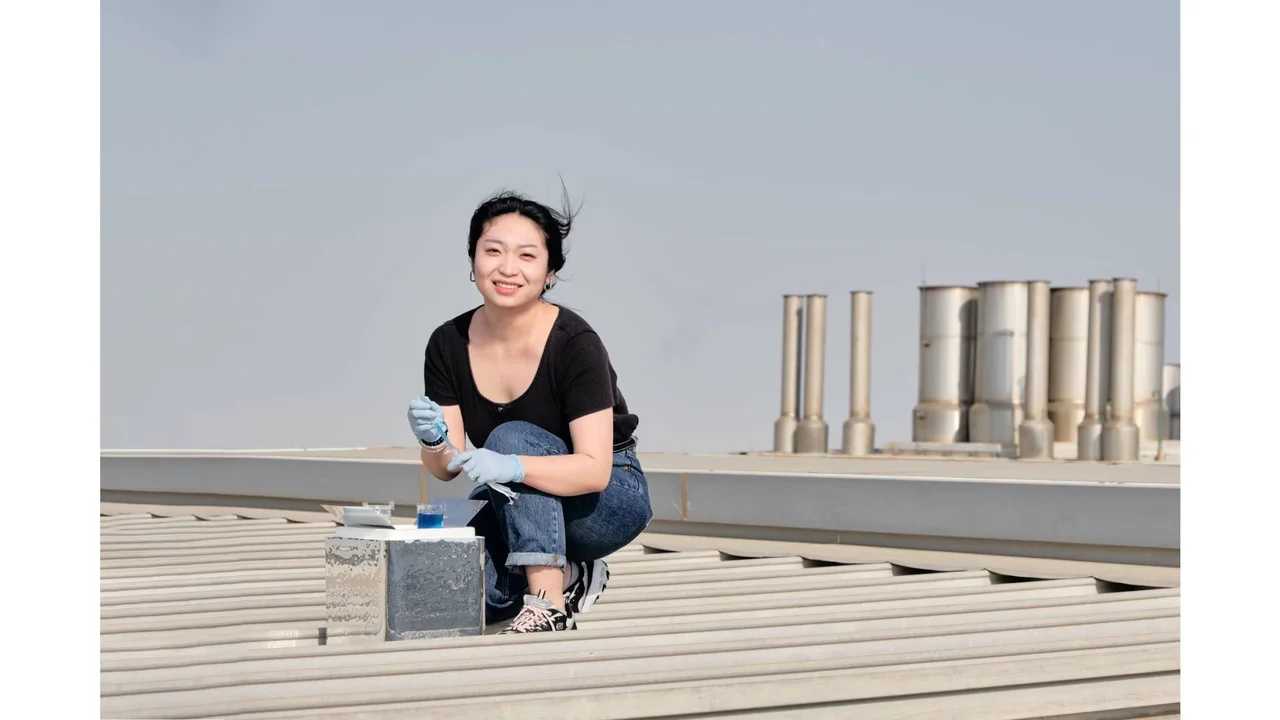

Zhang wondered whether the way around the problem was to use real sunlight, up on the laboratory roof. In late April, when the research was conducted, the roof surface was bathed in sunlight, and it was very hot.

“We had a lot of issues with the heat,” Zhang says. “But I had previously worked with materials scientist and engineer Qiaoqiang Gan, who I thought he could give us some advice.” With Gan, the team thermally insulated the reactor from the roof surface. “He helped us to optimize the whole setup, manage the temperature and get controlled conditions,” Zhang says. Over seven days, the membrane removed 92 percent of the dye in the water sample.

Finally, the team struck up one more cross-KAUST collaboration, with nanomaterials computational physicist Udo Schwingenschlögl, to establish the contribution of the membrane’s nanostructured surface to its photocatalytic activity. “That’s how this whole project was done,” Zhang says. “We’d encounter some issues, reach out to others to get their suggestions, and they would provide interesting ideas to help us move on to the next stage.”

The rooftop test suggests the collaborators’ material could be well suited to cleaning up household wastewater for water reuse applications, such as irrigating plants. “We hope to develop this technology into a point-of-use system for home use,” Ooi says. The material may be able to break down other organic contaminants, Ooi adds. “With further research, we also hope that this technology can be used for decomposing contaminants, such as pesticides,” he says.