By David Murphy

Zhiyuan Liu, a Ph.D. candidate in the KAUST Advanced Semiconductor Laboratory (ASL) under the supervision of Professor Xiaohang Li, received a Best Student Award at the 14th International Conference on Nitride Semiconductors (ICNS-14).

Held from November 12–17, 2023, in Fukuoka, Japan, ICNS-14 presented high-impact scientific and technological advances in materials, devices and applications based on nitride semiconductors. During the event, in-depth, independent sessions addressed the fundamental physics behind the critical issues in this field.

According to the event organizers, the Best Student Award [was] presented to young scientists who demonstrate[d] outstanding achievements in their paper, including abstract and presentation, and [are] expect[ed] to make significant contributions in the nitride semiconductor field.

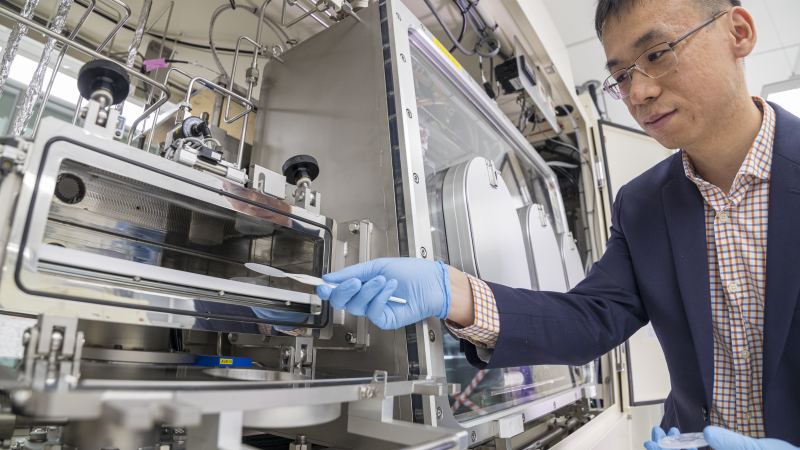

Liu’s ICNS-14 oral presentation, "Etching-free pixel definition in InGaN micro-LEDs through selective thermal oxidation method," outlined a KAUST-developed method for fabricating high-performance micro-LEDs. The work was conducted by members of the ASL team supervised by Professor Li.

“It is a deep honor for me to be recognized for the Best Student Award at another top nitride conference like the ICNS,” he noted. “I think this is also a notable recognition of our work from the conference committee.”

Improving micro-LEDs' energy efficiency

A key focus of Liu’s research is the development of ultrawide-bandgap semiconductor-based material growth, device modeling and fabrication. At present, he is working on the micro and nano-scale size InGaN and AlGaN-based visible and UV light-emitting diodes.

As reported in Liu’s ICNS-14 winning paper, the ASL team used selective thermal oxidation to form micro-LED pixels without using a conventional plasma etching technique. With this technology, the dielectric material effectively protects the areas used to emit light—LED pixels. In contrast, other non-pixel areas are oxidized during the thermal annealing in the air.

“The research is a world-first report that a selective thermal oxidation method has been applied to micro-LED fabrication,” he emphasized. “The problem [our work] solves is avoiding sidewall damage and defects typically caused by plasma etching, which significantly reduces device efficiency.

“As a low-cost, low-complexity and energy-efficient device manufacturing method, it dramatically improves current micro-LED performance and display resolution,” Liu concluded.