Reproduced with permission from reference 1 © 2020 American Chemical Society

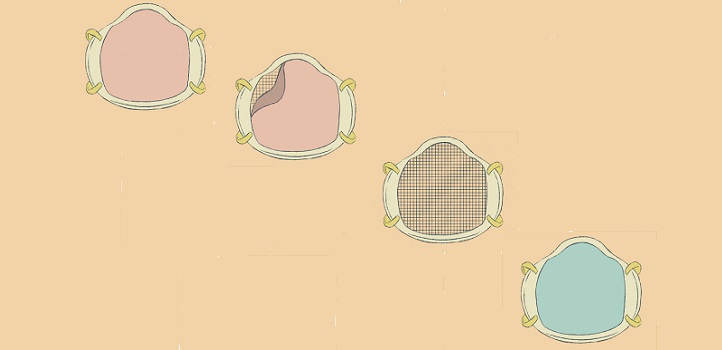

An ultrathin, lightweight, porous polymeric membrane designed at KAUST can turn the N95 respirator into a reusable facemask while potentially improving its ability to keep out SARS-CoV-2, the virus that causes COVID-19.

Governments around the world are requiring or advising citizens to cover their faces while in public places to help protect themselves and others from COVID-19 infection. The rise in demand for facemasks has led to global shortages and makeshift solutions.

The N95 respirator is a single-use, tight-fitting, surgical-grade mask that filters 95 percent of airborne particles. World health bodies and governments recommend their use only by healthcare professionals as these masks are in short supply.

Now, KAUST electrical engineer Muhammad Mustafa Hussain and his team have repurposed the N95 respirator by fabricating an attachable membrane that can be replaced after a single-use. The new design facilitates reuse of the N95 mask, saving costs, resources, and broadening its availability.

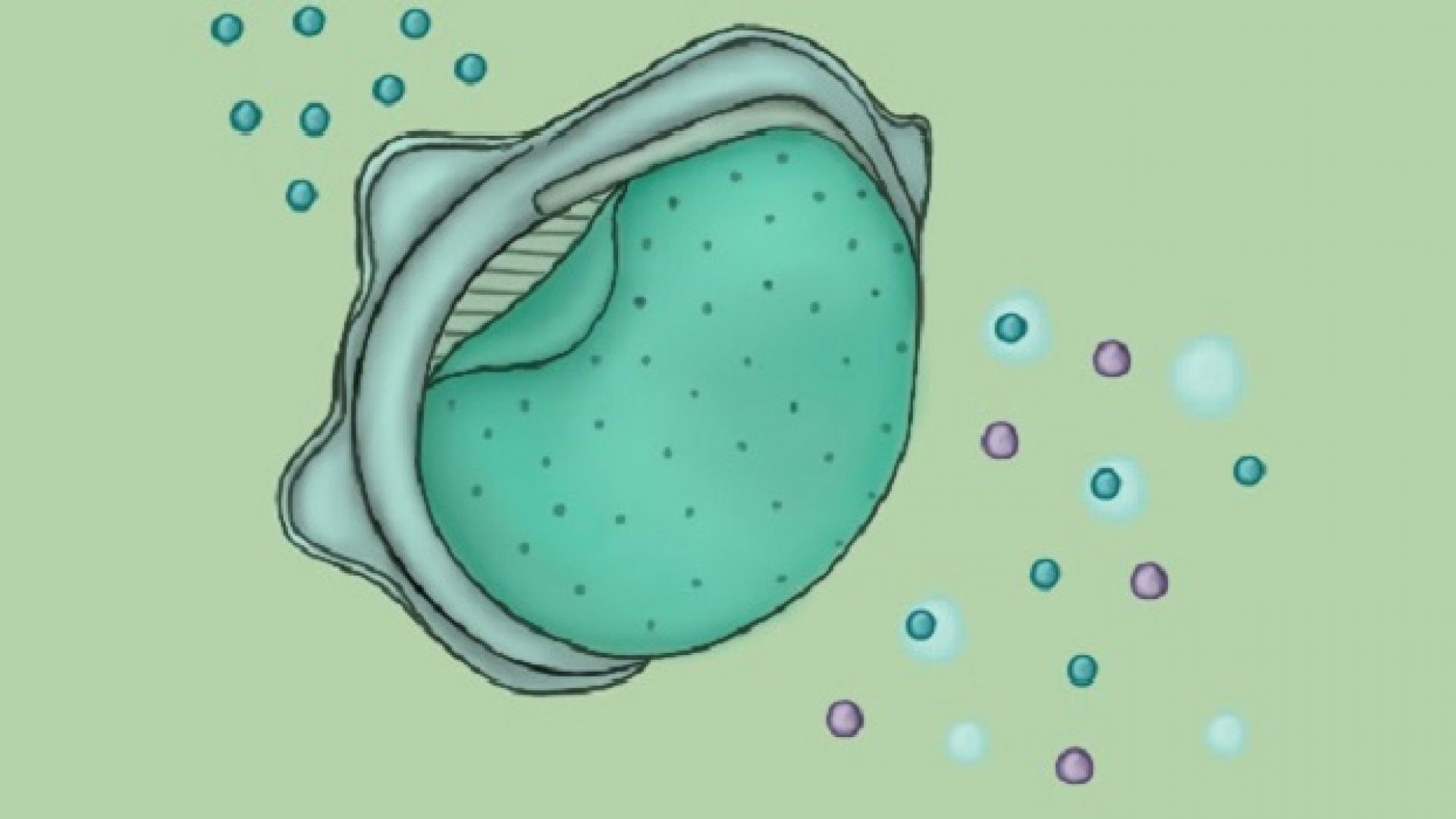

Importantly, it could also improve the mask’s filtration efficiency for SARS-CoV-2. Pores in currently available N95 masks are around 300 nanometers (nm) in size, while the SARS-CoV-2 virus is significantly smaller at 65 to 125 nanometers. The N95 is highly efficient at filtering out airborne particles but less so for particles smaller than the respirator’s pores.

The team’s approach facilitates the design of ultrathin polymeric membranes with pore sizes as small as five nanometers. The method first involves etching funnel-shaped pores into a silicon-based template, producing an array of 90 x 90nm squares on one side and tiny 5 to 55nm-sized pores on the other. "The etching method controls the distances between the pores and overcomes the problem of randomly spaced and oriented pores found in polymeric, nanoporous membranes developed by other researchers until now," explains Hussain.

Read the full article