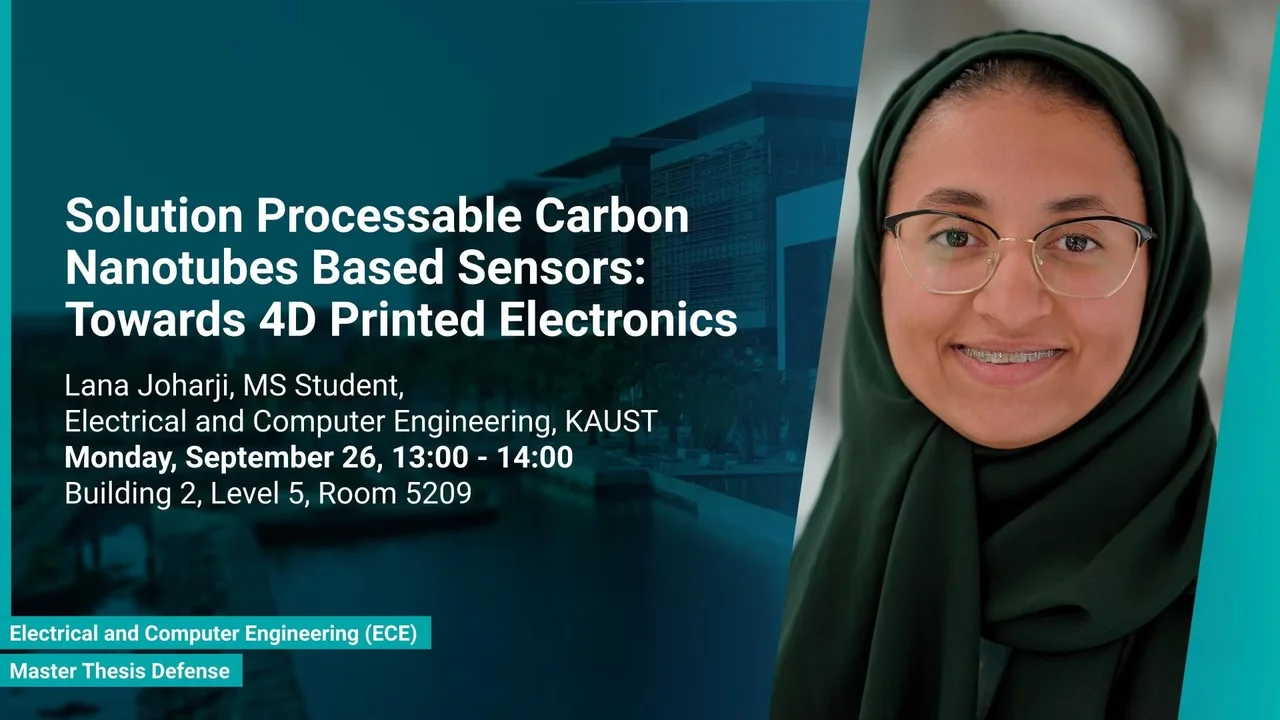

Solution Processable Carbon Nanotubes Based Sensors: Towards 4D Printed Electronics

In this thesis, we focus on the design and development of 4D printed sensors. Carbon nanotubes (CNTs) are used as the active sensing medium as they have proven to be ideal for application in sensors due to their high electric conductivity, stability, and mechanical flexibility. The effect of a heat-shrinkable substrate on the electronic and structural properties of CNTs is analyzed in depth, followed by the application in temperature, humidity, and pressure sensors. The results show that the 4D effect results in a more porous yet more conductive film due to an increase in the charge carrier concentration, enabling an improved sensitivity of the devices and allowing us to tune the selectivity based on the shrinking percentage. The developed device was fabricated using a rapid, cost-effective technique that is independent of advanced fabrication facilities to expand its applications to low-resource settings and environments.

Overview

Abstract

4D printing has recently gained a lot of interest where shapes with the ability to reconfigure based on external stimuli are found attractive especially when utilized to enhance the device performance. Nevertheless, most of the previously 4D printed devices have been focused on actuators. In this thesis, we focus on the design and development of 4D printed sensors. Carbon nanotubes (CNTs) are used as the active sensing medium as they have proven to be ideal for application in sensors due to their high electric conductivity, stability, and mechanical flexibility. The effect of a heat-shrinkable substrate on the electronic and structural properties of CNTs is analyzed in depth, followed by the application in temperature, humidity, and pressure sensors. The results show that the 4D effect results in a more porous yet more conductive film due to an increase in the charge carrier concentration, enabling an improved sensitivity of the devices and allowing us to tune the selectivity based on the shrinking percentage. The developed device was fabricated using a rapid, cost-effective technique that is independent of advanced fabrication facilities to expand its applications to low-resource settings and environments.

Brief Biography

Lana Joharji is a master’s student of SAMA Labs in the Electrical and Computer Engineering program at KAUST. She received her bachelor's degree in Electrical and Computer Engineering from King Abdulaziz University (KAU), KSA, in 2021. Her research interests include sensors, actuators, and flexible and soft electronics for environmental applications. She received the KAUST Graduate Fellowship for her MS/Ph.D. program. She is a student member of the IEEE and Saudi Council of Engineers.