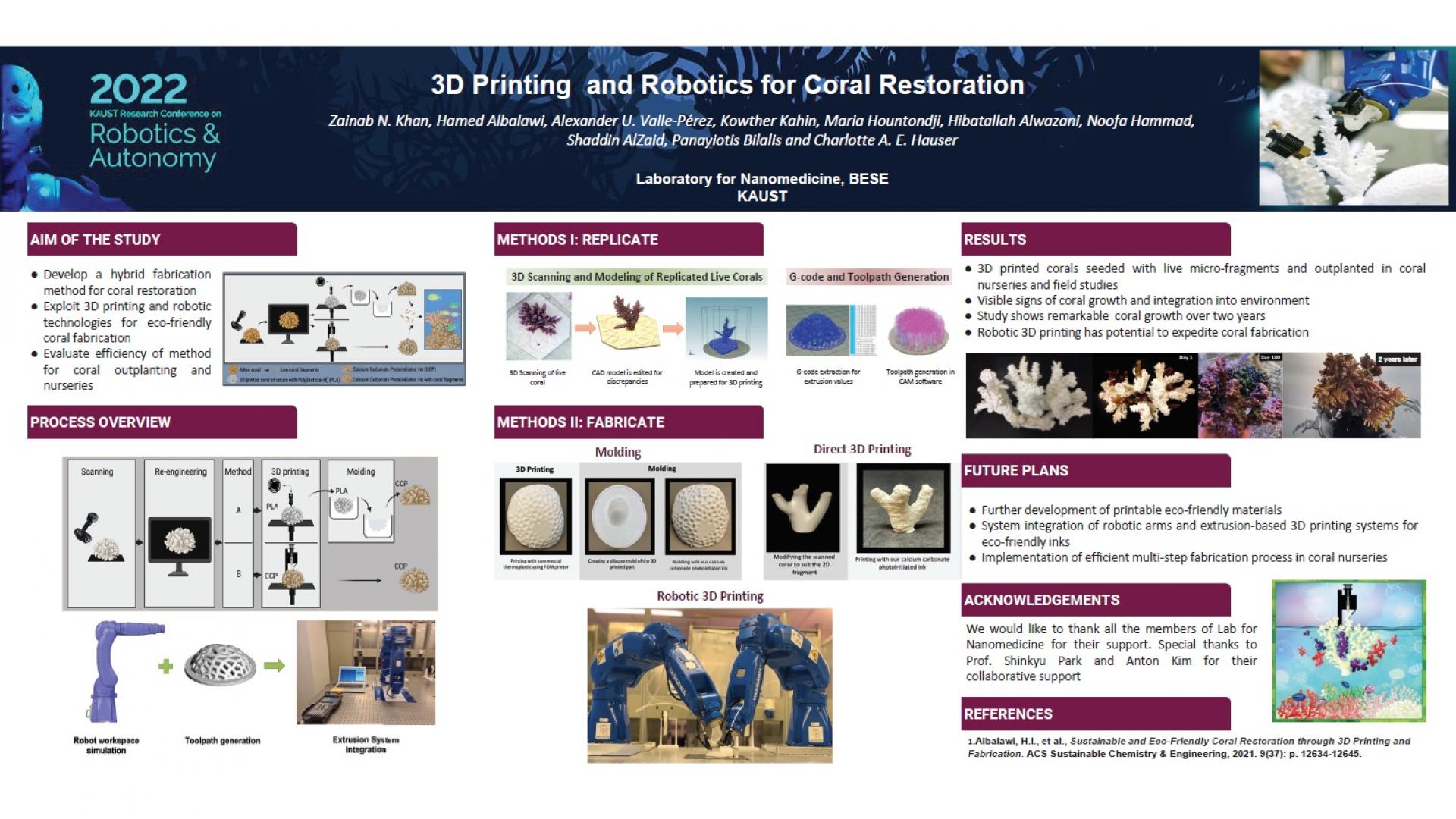

3D Printing and Robotics for Coral Restoration

Abstract

The fields of robotics and additive manufacturing are rapidly converging to reach new heights in several industries, including construction, automation and large-scale manufacturing. Given the added degrees-of-freedom in robotic arms, combined with the automated production of 3D printing, many applications can emerge with hybrid technologies for quicker, more accurate results. Tapping into this new niche, this research aims to merge the technologies of 3D printing and robotics for coral restoration. Coral reef degradation is a key area of concern, mainly caused by the spread of coral diseases, overfishing, pollution and marine heat waves. There is a pressing need to develop scalable methods for effective, cost-efficient restoration of coral ecosystems. While current approaches attempt to address this issue, they often rely on the use of synthetic materials, which could release toxic compounds in the long-term, and are severely limited in scalability. Hence, we propose a multi-step fabrication process which involves reverse engineering of live coral structures, fabrication of 3D coral replicas with eco-friendly inks, and propagation of live coral samples by micro-fragmentation. The first step involves obtaining live coral specimens from the Red Sea, and through 3D scanning, obtain a CAD model of the coral 3D construction with its complex geometries. The CAD model is modified to be better suited for the remaining steps. Next, the hybrid process of 3D printing and molding is implemented to fabricate 3D replicas of the desired CAD model. For ecologically friendly fabrication, a biocompatible ink has been developed, composed of Calcium Carbonate and plant-based resin. This Calcium Carbonate Photoinitiated (CCP) ink creates a coral-like structure that attempts to mimic the composition of living corals in order to generate a coral skeleton. The fabricated coral skeleton is then seeded with a select number of live coral fragments to enhance propagation. The result is eco-friendly coral-like skeletons seeded with live coral micro-fragments for expedited growth and restoration. Several batches of fabricated corals have been deployed in field studies and observed over 3 months with promising results, thus far. Another study was conducted with a fabricated PLA coral structure which was observed for over two years and found to assimilate well into the coral ecosystem and support the growth of coral fragments to more than double their original size. Through 3D printing technology, the process has proven to be effective for the reef transplantation process. However, to scale it for coral reef restoration on a practical level, industrial robots are to be deployed due to their larger workspaces, several degrees-of-freedom and added flexibility. This is achieved by converting simple g-codes into robot codes and generating a suitable trajectory for the desired construct. The robotic arm is mounted with a standard 3D printing extruder and loaded with the desired filament. The replica is 3D printed following the newly generated toolpath plan. By developing a robotic 3D printer, larger coral skeletons can be created at a faster rate with increased accuracy to enhance coral production and further expedite the transplantation process.

Brief Biography

Zainab is a Robotics Engineering graduate student from WPI in Massachusetts, USA. She has had the pleasure of working under Prof. Charlotte Hauser in the Laboratory for Nanomedicine at KAUST to develop robotic 3D printers for biofabrication. As a budding roboticist, she hopes to bring robotics and biofabrication a step closer to making a positive impact in environmental and health applications.