Researchers have shown recently that light can be twisted: a property called angular momentum of light that can be harnessed to overcome the capacity crunch faced by current data communications infrastructure.

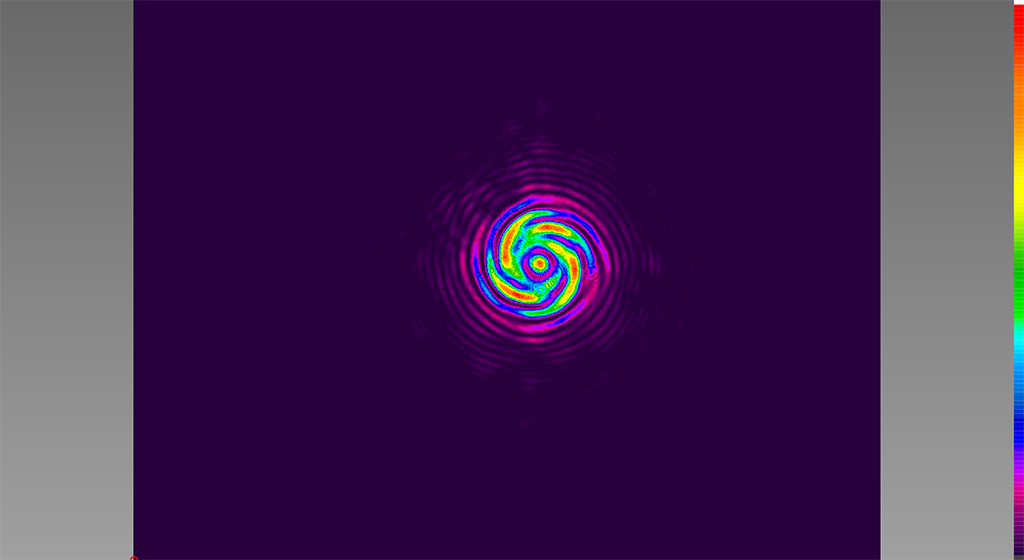

Beams with highly structured angular momentum are said to have orbital angular momentum (OAM), and can be formed into nearly infinite numbers of distinct vortex patterns. By combining multiple patterns into an optical beam, OAM-based communication can improve the efficiency of current data communication infrastructure.

Boon Ooi, Carlo Liberale and Slim Alouini from KAUST have now jointly developed an improved technique for generating OAM beams. They have used 3D printing to rapidly prototype devices, known as spiral phase plates, that can twist light with extreme precision. The team's 3D spiral phase plates are small enough to sit directly in front of laser sources found in microchips.

"We chose spiral phase plates for generating OAM beams because this structure provides straightforward integration into devices, such as fiber optic cables," says Edgars Stegenburgs, a Ph.D. student in Ooi’s Laboratory at KAUST.

© 2019 KAUST

"As well as being relatively simple to fabricate, the spiral phase plates produce high-purity OAM beams with minimal loses, which is vital for maintaining a sufficient signal-to-noise ratio,” explains Stegenburgs. “Evolving fields, such as quantum computing/communication, can benefit substantially from the development of experimental OAM demonstrations."

© 2020 Edgars Stegenburgs

Meeting the design parameters needed to generate OAM beams with low data error rates required several rounds of trial and error, a problem the team rapidly overcame with 3D modeling software.

"We try to match the desired laser wavelength with the OAM modes in the design phase and then import them to the 3D printer," says Andrea Bertoncini, a Ph.D. student in Liberale’s group. "We use this to systematically optimize the printing parameters to get the best surface for high-purity OAM beams. But there's always a tradeoff between the quality of the printed structures and the printing time."

Read the full article