Abstract

The structural integrity of wellbore casings and transportation pipelines is a critical aspect in the oil and gas industry for operational efficiency and environmental safety. Traditional non-destructive testing methods, while effective, face significant challenges in accurately assessing and monitoring these crucial infrastructural components, especially under harsh operating environments. Furthermore, the inner volume of these tubular structures and the flow speed of transported liquids pose additional difficulties upon the performance of devices designed to inspect their structures for defects and deformations.

To address the limitations of current electromagnetic inspection technologies for ferromagnetic tubulars, this dissertation formulates the inverse problems arising from tubular structural inspection as super-resolution imaging tasks. Frameworks that integrate innovative data acquisition methods with machine learning algorithms, particularly focusing on the development of hybrid neural networks as inverse models, are developed to overcome challenges in detection accuracy, characterization of internal and external wall defects, as well as the azimuthal localization of defects on multiple concentric tubulars. To extract spatio-temporal information from measurement data, the inverse models incorporate convolutional, recurrent, and customized layers in their architectures. These inverse models are designed to generate reconstructive images of pipelines and wellbores, facilitating high-resolution inspection utilizing minimal measurements. Moreover, the frameworks enhance the precision of defect characterization while adhering to the physical constraints of pipelines and wellbores.

Massively-parallelized simulation workflows are developed to create datasets of the electromagnetic profiles resulting from diverse collections of defects on ferromagnetic tubulars. The datasets enable pixel-by-pixel mapping from measurements to tubular structural visualizations to enhance generalizability and accuracy. Based on the acquisition methods, a series of inspection tools are developed and constructed as experimental prototypes. These prototypes acquire experimental data from new and used ferromagnetic tubulars, validating the performance of the proposed methodologies in real-world scenarios. Such experiments offer a more profound understanding of the optimal operational parameters of the inspection tools and the correlation between structural anomalies and their electromagnetic profiles. Furthermore, this dissertation provides systematic investigations into the minimum detectable defect dimensions, which is crucial for sensitivity analysis and establishing benchmarks for detection capabilities.

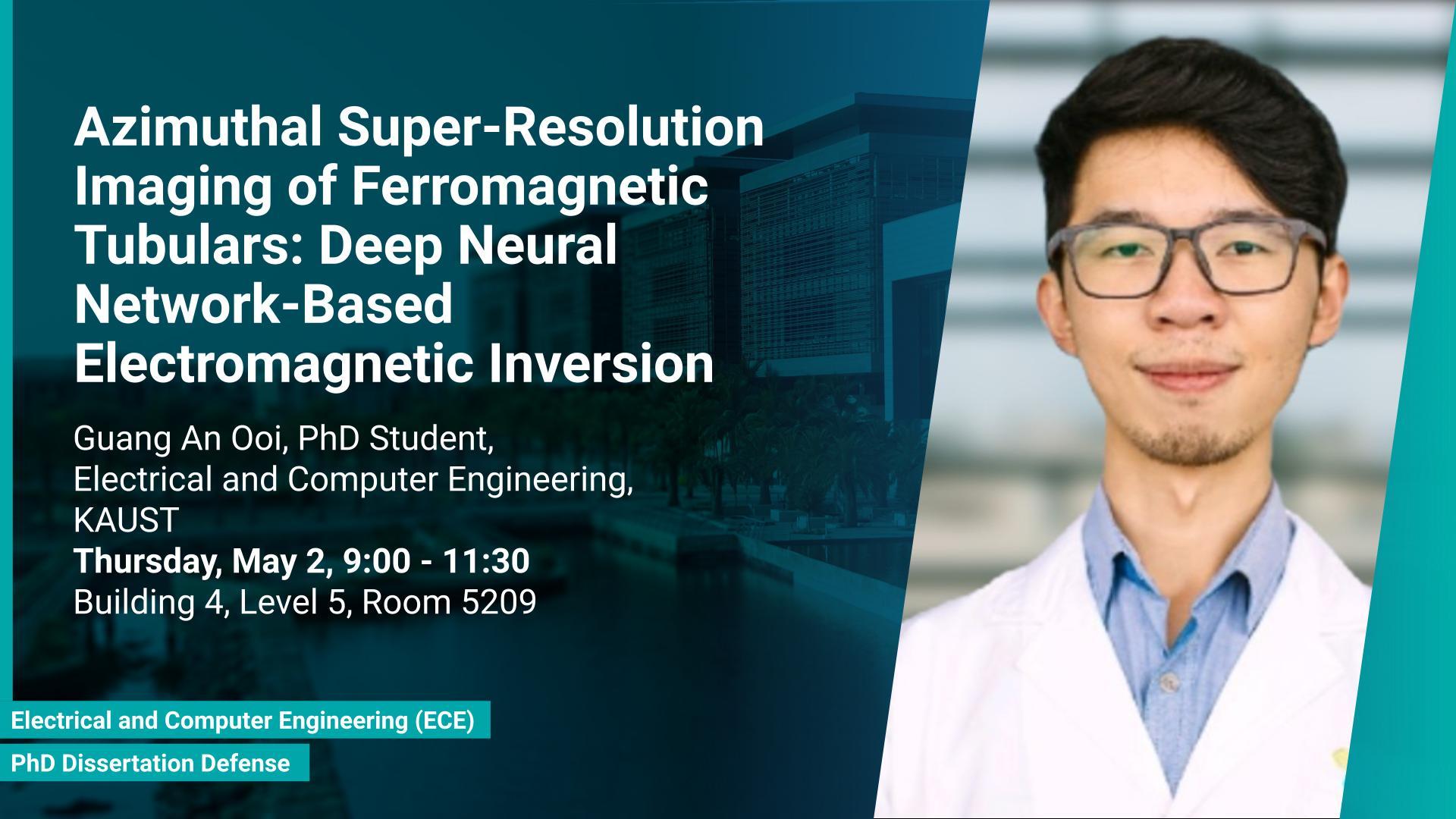

Brief Biography

Guang Ooi received the B.Sc. degree in Aeronautics and Astronautics Engineering from National Cheng Kung University, Taiwan 2017, and the M.Sc. degree in Electrical and Computer Engineering from King Abdullah University of Science and Technology (KAUST) in 2019. He is currently a Ph.D. student of Professor Shehab Ahmed at KAUST. His research interests include neural networks, electromagnetic inversion, drilling simulations, and power system simulation and control.