Event Start

Event End

Location

Abstract

Inertial sensing technologies, including accelerometers and gyroscopes, have been invaluable in numerous fields ranging from consumer electronics to healthcare and clinical practices. Inertial measurement units, specifically accelerometers, represent the most widely used microelectromechanical systems (MEMS) devices with excellent and reliable performance. Although MEMS-based accelerometers have many attractive attributes, such as their tiny footprint, high sensitivity, high reliability, and multiple functionalities, they are limited by their complex and expensive microfabrication processes and cumbersome, fragile structures that suffer from mechanical fatigue over time. Moreover, the rigid nature of beams and spring-like structures of conventional accelerometers limit their applications for wearable devices and soft-human machine interfaces where physical compliance that is compatible with human skin is a priority. In this dissertation, the development of novel practical resistive and capacitive-type inertial sensors using liquid metal as a functional proof mass material is presented. Utilizing the unique electromechanical properties of liquid metal, the novel inertial sensor design confines a graphene-coated liquid metal droplet inside tubular and 3D architectures, enabling motion sensing in single and multiple directions. Combining the graphene-coated liquid metal droplet with printed sensing elements offers a robust fatigue-free alternative material for rigid, proof mass-based accelerometers. Resistive and capacitive sensing mechanisms were both developed, characterized, and evaluated. Emerging rapid fabrication technologies such as direct laser writing and 3D printing were mainly adopted, offering a scalable fabrication strategy independent of advanced microfabrication facilities. The developed inertial sensor was integrated with a programmable system on a chip (PSoC) to function as a stand-alone system and demonstrate its application for real-time- monitoring of human health/ physical activity and for soft human-machine interfaces. The developed inertial sensor architecture and materials in this work offer a new paradigm for manufacturing these widely used sensors that have the potential to complement the performance of their silicon counterparts and extend their applications.

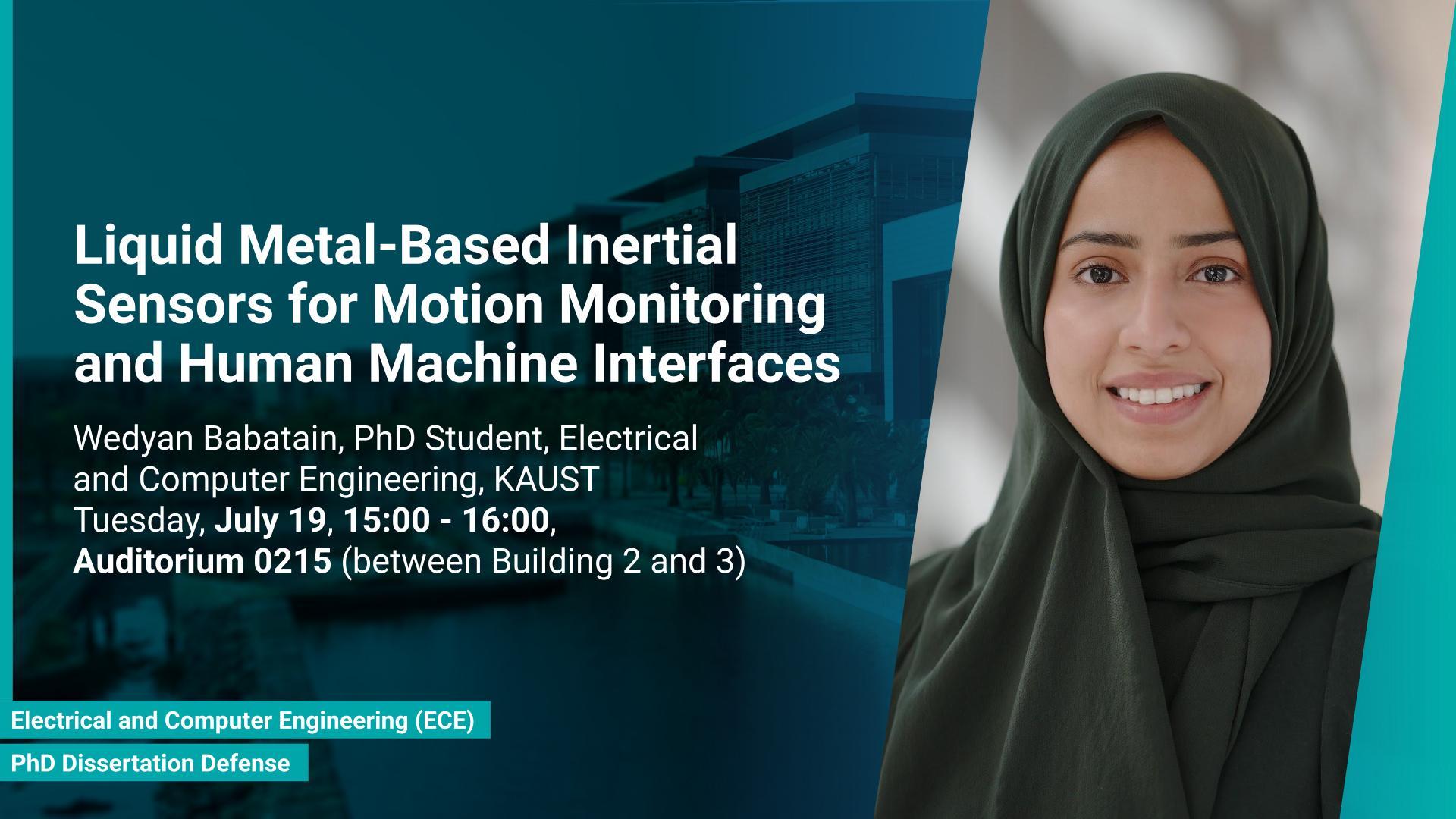

Brief Biography

Wedyan Babatain is a doctoral candidate of MMH Labs in the Electrical Engineering program at KAUST. She has an interdisciplinary background obtaining her bachelor's degree in Biomedical Engineering from the University of Delaware, USA, in 2017, and her master's degree in Electrical Engineering from King Abdullah University of Science and Technology (KAUST), KSA, in 2019. Her research interests include sensors, actuators, microfluidics, and flexible and soft electronics for healthcare and environmental applications. She was a finalist at the 2022 SXSW Innovation Awards and has presented her research projects prototypes at CES, SXSW, and IDTechEx. She received the King Abdullah Scholarship Program (KASP) awarded by the Ministry of Education to complete her undergraduate studies in the US and the KAUST Graduate Fellowship for her MS/Ph.D. program. She is a student member of the IEEE, BME society, and the secretary of the Electron Devices society chapter of western Saudi Arabia.