© 2018 Valeriya Chernikova

A porous material with tailor-made pockets stitched into its structure is a promising material for sensing noxious gases. A thin film of the material, coated onto an electrode, formed an electronic sensor that could detect traces of sulfur dioxide gas. The sensor is a significant step toward real-world devices that can sniff out dangerous gases in real air.

Although several lab-based analytical instruments can detect traces of a specific gas in the air, these instruments are typically large, expensive, power-hungry machines. There is still a need for small, inexpensive, energy-efficient sensors that, for example, could be widely deployed around industrial sites to continually monitor air quality.

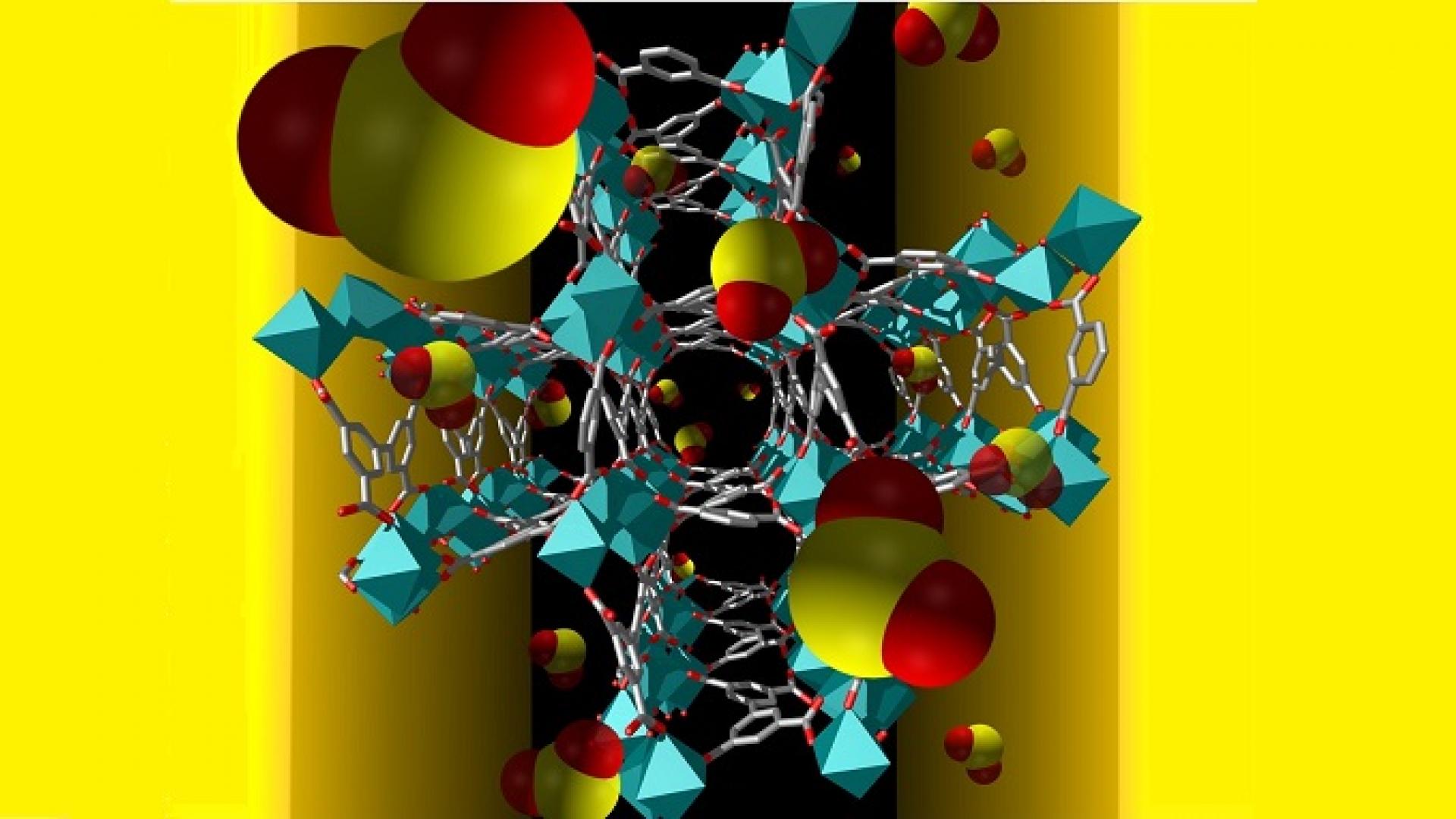

One promising way to make such sensors involves porous materials called metal-organic frameworks (MOFs). By making the MOF from different metal atoms and organic linkers, researchers can create materials that selectively absorb specific gases into tailor-made pockets within the structure. Two KAUST research groups, led by materials scientist Mohamed Eddaoudi and electrical engineer Khaled Salama, recently teamed up to develop MOF-based gas sensors.

The first step was completed in 2015 when the team made a proof-of-concept sensor by coating a MOF layer onto an electrode. The device senses gases in a similar way that a touchscreen senses a finger. The gas changes the MOF sensor’s capacitance, an electronic property that can be directly measured using the electrode.

Now, the team is working toward specific applications. “Our current work aims to identify the ideal MOF, in terms of sensitivity and selectivity, for detection of sulfur dioxide,” says Valeriya Chernikova, a Ph.D. student from Eddaoudi’s lab.

Read the full article