Achieving Precise Thermal Management in GaN HEMTs with Micro-Thin Film Thermocouples

As electronic devices become increasingly powerful, managing heat within components like Gallium Nitride (GaN) High Electron Mobility Transistors (HEMTs) is crucial. The latest publication in the TED Journal by Bhatti et al. introduces an innovative approach to addressing this challenge: integrating micro-thin film thermocouples (Micro-TFTCs) directly onto GaN HEMTs. This pioneering development allows precise, localized temperature measurements that significantly enhance the thermal management of these devices.

Why GaN and Why Now? GaN devices, prized for their high electron mobility and ability to operate at high power and frequencies, are indispensable in fields ranging from telecommunications to power electronics. However, the self-heating effect remains a concern, often leading to reduced performance and reliability. Traditional temperature measurement techniques, such as infrared thermography and Raman thermometry, fall short in accuracy, spatial resolution, or cost-efficiency. Micro-TFTCs present a new frontier by offering localized, accurate, and direct temperature measurements, helping to manage self-heating issues in real time.

The Technology Behind the Breakthrough Micro-TFTCs are fabricated using a platinum-chromium junction, achieving a sensitivity of 19.23 ± 0.405 μV/°C. Integrated directly into the GaN HEMT channel, these sensors provide real-time insights into the thermal gradients, especially between the gate and drain, where hotspots frequently occur. With a measured channel temperature of 68.54 ± 0.16 °C at a power density of 5.72 W/mm, these thermocouples enable precise monitoring without impacting the device's original performance.

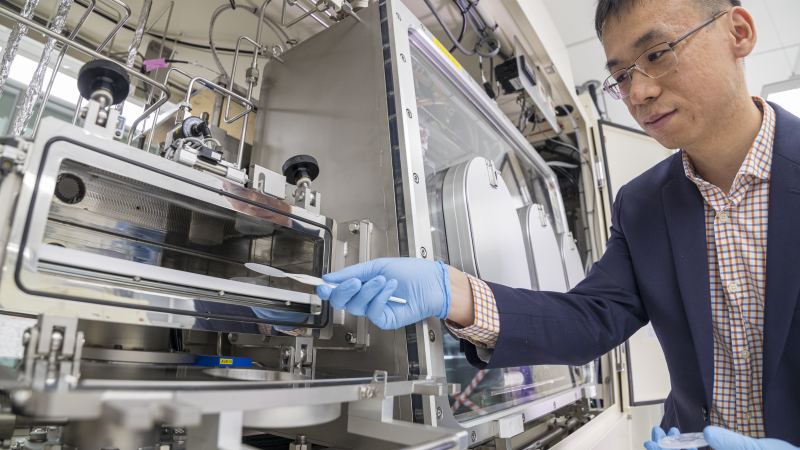

Innovative Fabrication and Calibration Techniques The research team employed advanced cleanroom techniques, including reactive ion etching and atomic layer deposition, to build the TFTCs with high precision. Calibration involved a custom-designed microheater and differential temperature measurement setup, ensuring reliability across a wide range of temperatures. The result? A method to measure thermal effects in microseconds, capturing even rapid thermal transients.

A New Path in Semiconductor Reliability and Efficiency This work by Bhatti et al. demonstrates a transformative solution for temperature measurement within semiconductor devices, paving the way for improved reliability and efficiency in GaN HEMTs. By minimizing self-heating effects through advanced thermal management, this development promises extended device lifespan and heightened performance—a vital breakthrough for industries relying on high-power electronics.