© 2020 KAUST

The advantages of light-emitting diodes (LEDs), such as their tiny size, low cost and excellent power efficiency, mean they are found everywhere in modern life. A KAUST team has recently developed a way of producing a white-light LED that overcomes some critical challenges.

Blinking away on almost every modern electronic device, LEDs transmit messages in their own distinct shade of red, green or blue. The coloration of an LED comes from a semiconductor inside that emits over a narrow spectrum of optical wavelengths. The inability of LEDs to emit across a wider spectrum restricts their use in lighting applications — emitting a wider spectrum is necessary to generate white light — or for displays that require a wide palette of different colors.

One approach to fabricate white-light LEDs is to combine devices of different materials, where each material emits a different color. The emission of red, blue and green from the different materials can be combined to create white light, but this increases the complexity and cost of manufacture of LEDs. Alternatively, a single semiconductor can be used by mixing in a phosphor that absorbs some of the light emitted by the semiconductor and then re-emits it as a different color. However, phosphor degrades over time, limiting the useful lifetime of these devices.

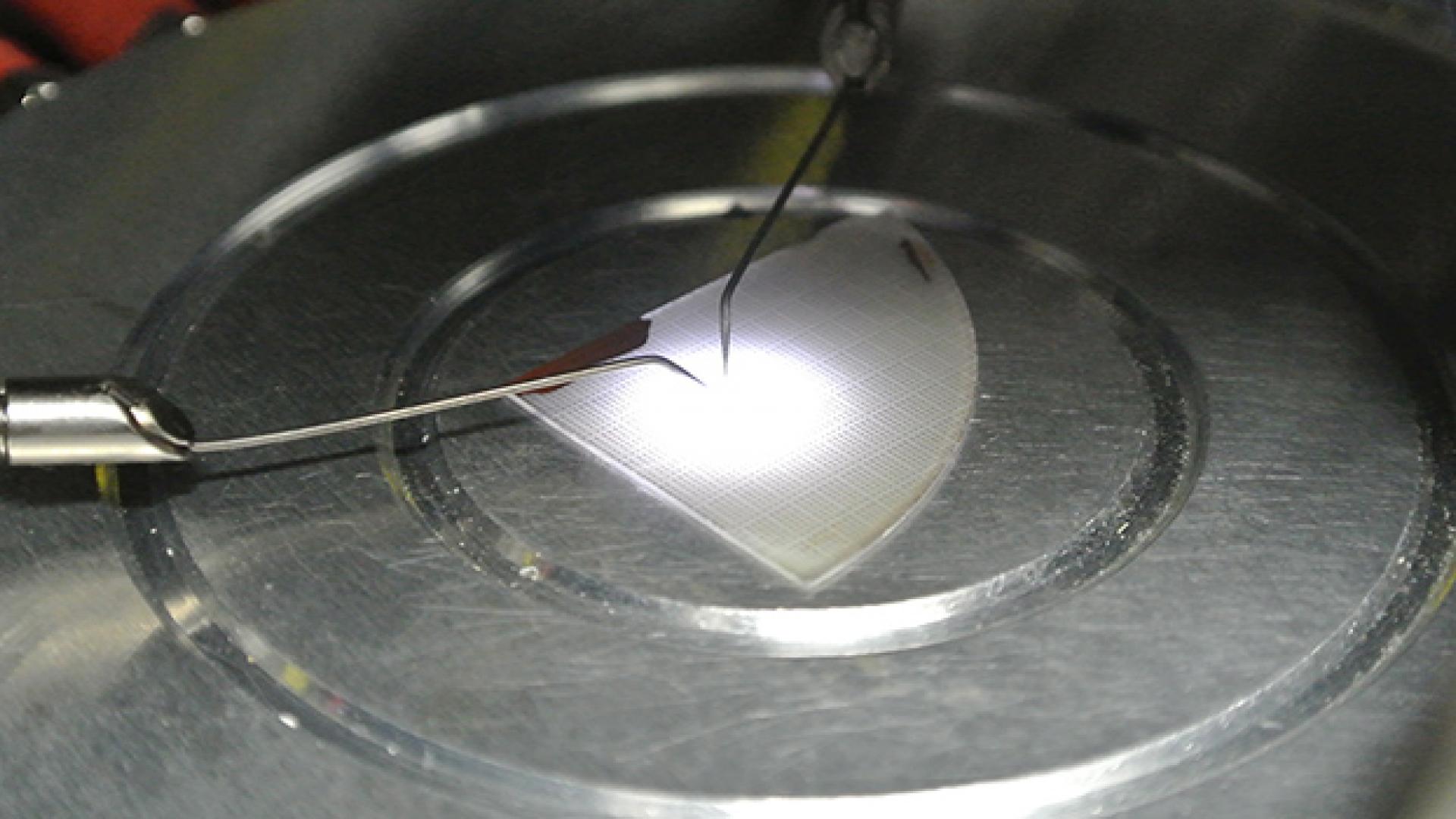

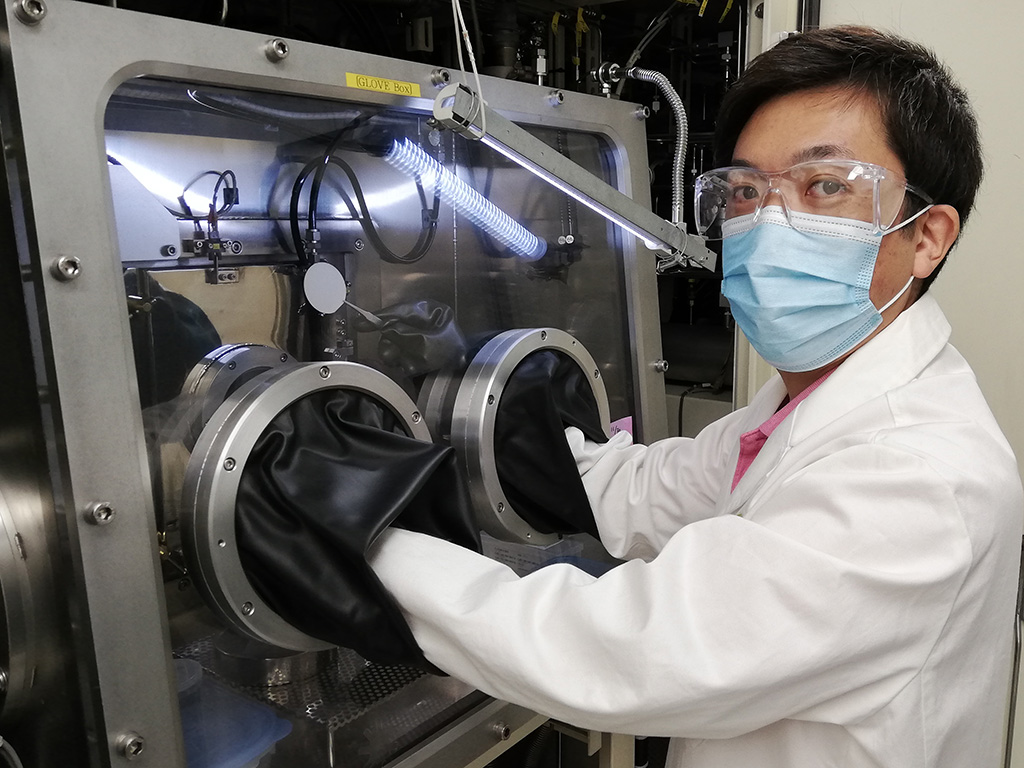

Daisuke Iida and Kazuhiro Ohkawa's team have devised a way to build phosphor-free monolithic white-light LEDs using the semiconductor indium gallium nitride.

Read the full article